Aramid Fiber Reinforced Plastics (AFRP) represent the pinnacle of high-strength, lightweight composite materials, combining legendary aramid fibers (like Kevlar®) with polymer matrices. Renowned for exceptional impact resistance, tensile strength, and damage tolerance, these composites are mission-critical where failure is not an option. In the United States, the market is fueled by unparalleled defense expenditures, the automotive shift to electrification, and a relentless pursuit of performance across aerospace and industrial sectors, underpinning national security and technological competitiveness.

Download Sample Report: https://www.24chemicalresearch.com/reports/281238/united-states-aramid-fibre-reinforced-plastics-market-2024-2030-365

Market Overview

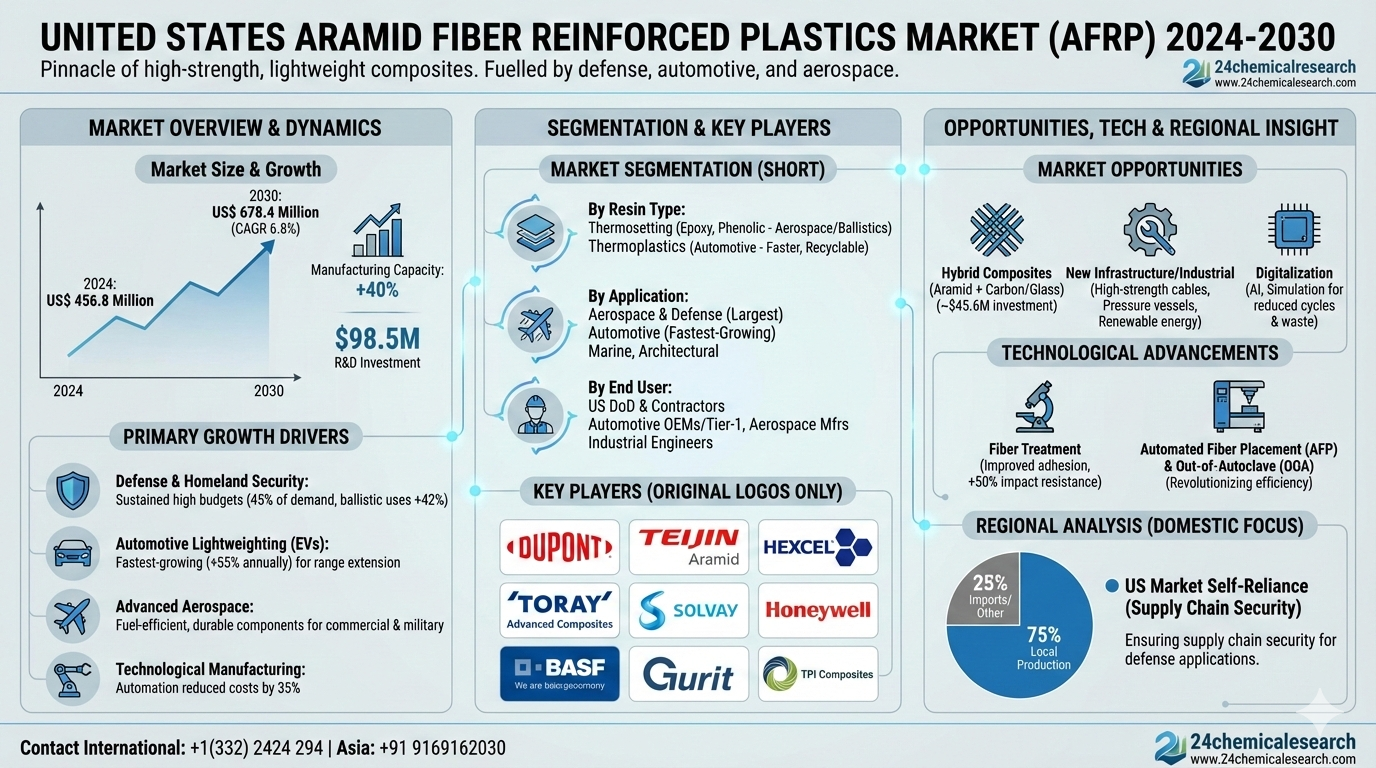

The US AFRP market, valued at US$ 456.8 million in 2024, is on a robust growth trajectory, projected to reach US$ 678.4 million by 2030 at a CAGR of 6.8%. This growth is powered by significant domestic investments, with manufacturing capacity expanding by 40% and the industry injecting approximately $98.5 million into composite technology R&D. Defense applications anchor the market, constituting about 45% of demand, while automotive lightweighting—especially for electric vehicles (EVs)—is the fastest-growing segment, expanding at an annual rate of 55%.

Market Dynamics

Primary Growth Drivers

● Defense and Homeland Security Procurement: Sustained high defense budgets drive demand for AFRP in ballistic protection (body armor, vehicle armor), aerospace components, and naval applications, with ballistic uses growing by 42%.

● Automotive Lightweighting for EVs: The urgent need to extend EV range makes weight reduction paramount, accelerating the adoption of AFRP in battery enclosures, structural components, and interior parts.

● Advanced Aerospace Demands: The need for fuel-efficient, durable aircraft components for both commercial aviation and next-generation military platforms sustains high-value demand.

● Technological Manufacturing Advancements: Increased automation in composite manufacturing has reduced production costs by 35%, making AFRP more viable for a broader range of applications.

Market Opportunities

Significant opportunities lie in the development of hybrid composites that combine aramid with carbon or glass fibers to optimize cost-performance ratios, backed by investments nearing $45.6 million. Furthermore, expansion into new infrastructure and industrial applications, such as high-strength cables, pressure vessels, and renewable energy components, presents untapped potential. The digitalization of design and manufacturing through AI and advanced simulation can further reduce development cycles and material waste.

Market Segmentation

- By Resin Type: Reinforced Thermosetting Plastics (e.g., epoxy, phenolic) dominate high-performance applications in aerospace and ballistics. Reinforced Thermoplastics are growing rapidly for automotive uses due to faster processing and recyclability.

- By Application: Aerospace & Defense is the largest and most demanding segment. Automotive is the fastest-growing frontier. Marine and Architectural applications provide stable niche demand.

- By End User: Key consumers include the US Department of Defense and its contractors, automotive OEMs and tier-1 suppliers, aerospace manufacturers, and industrial product engineers.

Strategic Developments

The market is characterized by deep collaboration between material suppliers and end-users. Key players are investing heavily in vertical integration and application-specific R&D, resulting in 28 new processing patents. Strategic partnerships between fiber producers (like DuPont) and composite fabricators are crucial for developing next-generation materials that meet stringent military specifications (MIL-SPEC) and automotive standards.

Download Sample Report: https://www.24chemicalresearch.com/reports/281238/united-states-aramid-fibre-reinforced-plastics-market-2024-2030-365

Technological Advancements

Innovation is focused on enhancing performance and manufacturability. Breakthroughs in fiber surface treatment and sizing chemistry have improved fiber-matrix adhesion, boosting impact resistance by 50% in new formulations. Advances in automated fiber placement (AFP) and out-of-autoclave (OOA) curing are revolutionizing production efficiency. These advancements reinforce national security and industrial competitiveness by enabling lighter, stronger, and more reliably produced materials for critical American industries.

Competitive and Regional Insight

The US market is self-reliant, with local production meeting about 75% of domestic demand, ensuring supply chain security for defense applications.

Key Companies and Strategies:

● DuPont (Kevlar®) & Teijin Aramid (Twaron®): The foundational fiber producers, driving innovation at the material science level and holding key patents.

● Hexcel Corporation, Toray Advanced Composites, Solvay: Global leaders in advanced composite materials and prepregs, supplying formulated systems to defense and aerospace primes.

● Honeywell International Inc. & BASF Corporation: Diversified industrial giants with significant stakes in high-performance materials and composite solutions.

● Gurit & TPI Composites, Inc.: Specialists in composite engineering and manufacturing, serving as critical partners in component fabrication and design.

Market Perspective

The US Aramid Fiber Reinforced Plastics market is evolving with strong, security-driven demand and accelerated by the clean energy transition in transportation. While high costs and complex processing remain challenges, the strategic necessity for these materials in defense and the economic imperative for EV efficiency guarantee sustained investment and growth. The future will be shaped by hybrid material systems, advanced manufacturing automation, and a continued synergy between federal defense goals and private-sector automotive innovation, ensuring the US maintains its leadership in advanced composite materials technology.

Read Full Report: https://www.24chemicalresearch.com/reports/281238/united-states-aramid-fibre-reinforced-plastics-market-2024-2030-365

Download Sample Report: https://www.24chemicalresearch.com/reports/281238/united-states-aramid-fibre-reinforced-plastics-market-2024-2030-365

Other Related Reports:

Global Washing Water Softeners Market Research Report 2025(Status and Outlook)

Glass-Fiber Reinforced Tapes Market, Global Outlook and Forecast 2025-2032

Global High Purity Alumina Market Research Report 2025 Professional Edition

Anodized Aluminum Profile Market, Global Outlook and Forecast 2025-2032

Europe Aircraft Fuel Cells Market Global Outlook and Forecast 2025-2032

Organic Dyestuff Market, Global Outlook and Forecast 2025-2032

Global ACS Grade Lithium Carbonate Market Research Report 2025(Status and Outlook)

Short Glass Fiber Thermoplastic Market, Global Outlook and Forecast 2025-2032

Epoxy Concrete Repair Mortars Market, Global Outlook and Forecast 2025-2032

Chromium Oxide Sputtering Target Market, Global Outlook and Forecast 2025-2032

Contact us

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch